|

|

Joined:

August 2003

Posts: 888

Location: Louisville, OH 44641 | Hey folks:

Anyone playing an Ovation with one of the hand laid Fiberglass Bodies? Is there a big difference between the Fiberglass Bodies and the molded ones?

And as a modernized update, couldn't these bodies be made today from Carbon Fiber...like the Adamas Tops? You know, super thin but strong. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Until 1981 all Ovations had hand-laid woven cloth bowls. But, not all hand-laid bowls are the same.

The first generation bowls were vacuum-bagged over male molds and were scraped to remove excess resin.

The second generation were laid up inside female molds with no vacuum.

The current generation are laid up inside female molds, but are vacuum-bagged inside an autoclave.

The purpose behind vacuum bagging is to remove excess resin, which only adds weight, not strength. In the case of the fiberglass bowls, the thinner the bowl, the more resonant it is.

IMO, yes, there's difference between the hand-laid bowls and the SMC bowls. Besides being lighter, they're also more resonant. I personally prefer the woven bowls over the SMC bowls.

Right now I've got a 1967 1st gen bowl guitar at my house and I've got a 1976 2nd gen bowl guitar. The 1st gen bowl slightly edges out the 2nd gen bowl in resonance, a.k.a. belly rumble. I have not played a 3rd gen bowl guitar, but I would imagine it's a lot like the 1st gen bowl because the excess resin is squeezed out by the vacuum bagging and higher pressure inside the autoclave. I've got a 3rd gen bowl (just the bowl, not a guitar) and it's very thin.

The hand-laid FG bowls are two plies of 6-oz 2x2 twill. When excess epoxy is scraped off, this results in a shell that's about 3/64" thick. Here's a pic:

CF is stiffer than FG. So, if CF were the same thickness as FG, it would be less resonant. To have the same resonance, the CF bowl would have to be thinner. How much, I couldn't say. |

|

| |

|

Joined:

August 2003

Posts: 888

Location: Louisville, OH 44641 | Sounds like I need to find one of these and play it. At 3/64", it is just over 1 mm thick! Very impressive.

So Dan, where in the world did you go shopping for this 3rd generation FG Body you have? |

|

| |

|

Joined:

August 2003

Posts: 888

Location: Louisville, OH 44641 | Sounds like I need to find one of these and play it. At 3/64", it is just over 1 mm thick! Very impressive.

So Dan, where in the world did you go shopping for this 3rd generation FG Body you have? |

|

| |

|

Joined:

December 2003

Posts: 855

Location: Canada | Did Q181 have a fiberglass or carbon fiber bowl? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | stellarjim - 2015-11-02 10:48 AM

Sounds like I need to find one of these and play it. At 3/64", it is just over 1 mm thick! Very impressive.

So Dan, where in the world did you go shopping for this 3rd generation FG Body you have? It could be as thick as 1/16". (1.5mm) I didn't measure it at the time. I just know that 2 plies of 8.5-oz twill (not 6-oz., like I wrote previously) made a patch that was exactly the same thickness as the bowl. It was thrown into the deal when I bought my 1619 CL. I used it as the mold to make the patch for the hole in the back of the 1619 body.

Edited by DanSavage 2015-11-02 1:44 PM

|

|

| |

|

Joined:

April 2008

Posts: 2985

Location: Sydney, Australia | Like Dan, I think the hand laid bowls are more resonant. I think it's a big part of the reason that the 08C is so good. |

|

| |

|

Joined:

June 2012

Posts: 2345

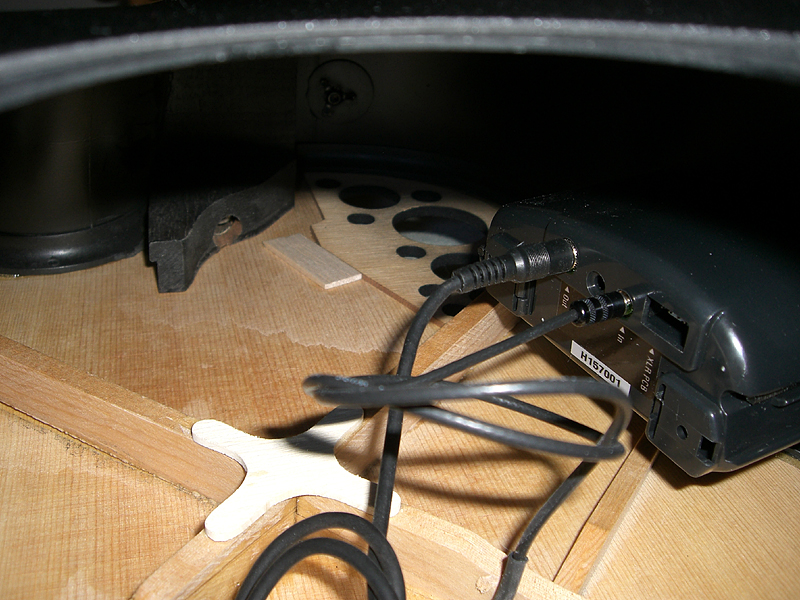

Location: Pueblo West, CO | IMO, there was one other thing the 1st gen bowls had going for them and that's the thin, molded fiberglass kerfing. This was changed in later generations to a solid plastic kerfing, but I believe it made the tops less responsive. Here's the 1st gen kerfing.

Here's the 2nd gen kerfing.

IMO, the 1st gen kerfing acted like the Adamas suspension ring. Here's a pic of a cross-section of the suspension ring. Later kerfing (Upper left in pic) is similar to the suspension ring in that the underside is radiused, but IMO neither are as flexible as the original molded fiberglass kerfing.

|

|

| |

|

Joined:

April 2008

Posts: 2985

Location: Sydney, Australia | I think it had a carbon fibre body (and neck). Ovation decided they were too expensive to make, so they never went into production and only a handful were made. Beal might chip in around now ... |

|

| |

|

Joined:

December 2001

Posts: 7243

Location: The Great Pacific Northwest | It's very hard to compare the bowls. Lets not forget when the LX series was introduced not only did the contour bowls come into play, but also the addition of the glass beads which seemed to make them more resonant as well as lighter. It's literally a balancing act... getting a light enough bowl that resonates without making the guitar neck heavy. Quite a feat. The OFC2 with hand-laid, contour bowl I think is the best... but.. that's subjective too I guess. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Mr. Ovation - 2015-11-02 2:43 PM

It's very hard to compare the bowls. Lets not forget when the LX series was introduced not only did the contour bowls come into play, but also the addition of the glass beads which seemed to make them more resonant as well as lighter. It's literally a balancing act... getting a light enough bowl that resonates without making the guitar neck heavy. Quite a feat. The OFC2 with hand-laid, contour bowl I think is the best... but.. that's subjective too I guess.

Yep. I was drawing broad generalizations. It's possible to get a good-quality layup in a female mold that matches the resin content of a vacuum-bagged layup over a male mold. The primary difference is that the vacuum-bagged layups will have a more consistent thickness on a day-to-day basis.

The addition of the microballoons (glass beads) reduces the density of the resin matrix. Because the resin is less dense, it is lighter and vibrates more freely, a.k.a. resonate.

As you say, in a production environment, it's a balancing act between producing the best product with the least amount of labor. In manufacturing, time is money. Spending more time to produce a product has two drawbacks, number one, it costs more because of the man-hours involved and secondly, it reduces the number of products that can be made in a given period of time.

The GS SMC bowls result in a product that comes close to rivaling the features of the hand-laid bowls in a fraction of the time. That's also why composite manufacturers use autoclaves. The heat reduces the cure time of the epoxy enabling more parts per day to be produced. |

|

| |

|

Joined:

June 2002

Posts: 6202

Location: Phoenix AZ | d'ovation - 2015-11-02 12:32 PM

Did Q181 have a fiberglass or carbon fiber bowl?

The bowl on the Q is carbon fiber |

|

| |

|

Joined:

June 2002

Posts: 6202

Location: Phoenix AZ |

|

|

| |

|

Joined:

December 2014

Posts: 1713

Location: Frozen Tundra of Minnesota | Is the neck on the Q also carbon fiber, in one piece with the body, then a wooden fretboard? |

|

| |

|

Joined:

June 2002

Posts: 6202

Location: Phoenix AZ | Yes that's correct. |

|

| |

|

Joined:

December 2014

Posts: 1713

Location: Frozen Tundra of Minnesota | Thank you! What stopped these from being produced for the market? They seem to have been light years ahead of their time! |

|

| |

|

Joined:

April 2008

Posts: 2985

Location: Sydney, Australia | <p>They were very expensive to make, and therefore very expensive to buy. They figured there wasn't the market. Be nice if they revisited those calculations, given CF is now more affordable.</p>

Edited by TAFKAR 2015-11-03 10:40 PM

|

|

| |

Fiberglass Bodies

Fiberglass Bodies Fiberglass Bodies

Fiberglass Bodies