|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "Believe me when I say that some of the most amazing music in history was made on equipment that's not as good as what you own right now." - Jol Dantzig |

A beginners guide to re-fretting your guitar A beginners guide to re-fretting your guitar

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Written for beginners by a beginner. These are tools and methods which have worked for me on Ovations. Real experts may have different ideas on the topic... This will be a multi-post series covering pretty much all you need to know in order to do a superb job refretting your prized guitars. Much information is available on Youtube, various sites of professional luthiers, and on StewMac. I don't intend to duplicate all that, rather this is a supplement which covers all those little details and questions the amateur has but the pros don't cover. So you have a guitar which might need some new frets. You have a ton of questions: Can I do this myself? Which tools do I need? Which tools aren’t worth buying? How much will it cost to do it myself? Does it need an entire refret or only a few frets replaced? If you’re like me, you scoured the internet for articles, videos, and merchant websites but really didn’t get the important questions answered. So let’s get some helpful answers for you. First: YES, you can do this! You definitely need to have some specialized tools and a little bit of practice. If you’ve done home improvement projects, built models, or done minor mechanical work on your car or bicycle then you probably have plenty of natural ability for fret work. Second and Third: I’ll walk you through a comprehensive list of necessary tools and materials, plus those which would be nice but are not necessary. I’ll also name some which are better than others, and those which will likely be a waste of your money. Last: The tools and materials you need will cost around $350 to $500. Each additional fret job will only cost the price of fret wire, perhaps $12 to $20. You may need a new nut (likely). Nut tools will cost $50 to $140, plus blank nut cost of $5 to $15. Considering that a professional refret will cost around $400 - $500, and a professionally installed new nut will cost around $75, there is financial justification to take on this job yourself, especially if you have more than one guitar needing new frets. Basic Advice: Use an old guitar to learn how to refret and cut a new nut. After this one job you’ll be ready to take on one of your prized instruments. You really don't want to do your first fret job on a good guitar. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Tools:  From left to right, top to bottom. Caliper: This tool measures to the .001 of an inch. Almost necessary, definitely very helpful. Use it to measure your existing fret dimensions (width, height, and tang). Also very helpful measuring nuts, nut slots, saddles, etc. StewMac fret rocker: This heavy tool is perfect for finding a high or low fret. Very helpful for finding and fixing a few trouble spots, but you don’t need this tool for a total refret or an overall fret leveling job. Fret Guru fret tool: Does the same functions as the StewMac fret rocker, plus several others. This is the tool to get (though I like the StewMac tool better for finding a high fret). It has fret height notches to determine if your frets are too worn to file them down to level. It has several different measurement markings for setting up nut slots, bridge height, and truss rod adjustment. www.Fretguru.com Fret puller: An absolute necessity. Flush ground and fairly narrow to get under frets easily. Spring loaded for easy use. You might find a cheaper set of nippers at the local hardware store and grind them down, but these work great and are reasonably priced. Chip preventers: Not necessary but they really do work. Slide one under the fret as you are pulling it to prevent the fretboard from chipping out. Well worth the money. They save you a lot of time, fiddling, and frustration fixing chipouts. Fret cutter: Necessary. This is a heavier and larger tool than the fret puller. Used to cut fret wire before installation and then to trim the ends right after installation. Fret slot cleaning tool: A curved blade which fits a regular Xacto handle. I’d call it necessary, but you could use a regular Xacto type of knife instead. But these are so cheap and they work so well, just get one of these. If you already have an Xacto handle, just buy the blade. Edited by FlySig 2014-09-22 11:05 PM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah |  Syringe: This is a veterinary syringe sold by StewMac. Very helpful, almost a necessity. Use it to inject glue into fret slots or other tight places. Buy the mid sized needles. Smaller may work, but the largest won’t fit in the fret slots. Feeler Gauge (thickness): Basic automotive feeler gauges are very helpful but not a necessity. Use the gauge to measure the width of your existing fret slot to be sure you buy the correct fret wire. Alternatively you can measure the existing fret wire tang with calipers, but it is more accurate to measure the slot itself. Fret Hammer: Any version of fret hammer is fine. A necessity. Don’t use a regular hammer to install frets! Refret Saw: This is StewMac’s refret saw. It works but I recommend their Japanese fret slot cleaning saw instead. (NOT the Japanese fret saw, but the fret slot cleaning saw). If the StewMac refret saw slips, the other saw blade can hit the edge of the neck and damage it. If your guitar has binding on the neck you will need a small saw of this style. If there is no binding you can use a regular fret saw, in which case look for one with a depth stop. Be sure the blade width is less than (or equal to) the tang width of your fretwire. Tangs are usually .023”. A .020” blade works fine. Radius Gauges: A necessity for a really perfect fret job. Use to measure your fretboard radius before and after sanding. Ovations are 10” radius, but if it’s been sanded by someone else it could be different. As you’re sanding, use the radius gauge to verify you have gotten the fretboard properly shaped along the entire length. A perfect wood surface is the foundation of a really good fret job. Edited by FlySig 2014-09-22 11:06 PM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah |  Bevel File: Use this to put a bevel on the edges of the new frets. I call this a necessity but you could hold a file by hand at an angle to file the edges. This tool is way better than doing that! I got this file from CB Gitty. Be sure the narrow edge of the file is very smooth. If it contacts the top of the guitar it can damage the finish if there are any file teeth left at all. Use a grinding wheel and 400 grit wet/dry sandpaper to get that edge really smooth. Fret Crowning File: Almost a necessity. Has concave edges which file the top of the fret to the proper shape. You could use a small flat file to round off the top of the fret but that is a lot of work and prone to damaging frets and fingerboard. Buy a crowning file which matches the crown dimensions of the fret wire you will be using. Fret End File: Small file for carefully filing the ends of the installed frets flush with the edge of the neck and for smoothing the ends. The narrow dimension of this file is smooth so as not to damage the wood. Necessary! Triangular File: Optional. You can smooth the three corners of a regular file so it won’t damage the wood. This file could be used to crown frets and to file the ends. I really don’t recommend this method. File cleaning brush: The files will clog with debris and need to be cleaned. This little brass brush from StewMac works better than other file cards or file brushes because the bristles are very small. It is actually a “Brass Scratch”, but works great as a file cleaner. Edited by FlySig 2014-09-22 11:06 PM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah |  Precision Straight Edge: Necessity! Get the 18”. You have to get the neck straight before sanding by adjusting the truss rod. This tool is also used to verify you have sanded the wood properly. It also confirms your frets are leveled properly. The notched straight edge may be useful for partial refrets but costs more. Using the next tool in the photo, the fret/fingerboard leveler, to check for level is very difficult. If you are really trying to cut costs to an absolute minimum, you could try to get by without the Precision Straight Edge. In which case loosen the truss rod completely and then sand the fretboard level. Fret/Fingerboard Leveler: 16” long precision ground flat sanding beam. Necessity. This tool sands the wood or the frets to a very straight line. If there are any humps or low spots in the neck, this is the tool to remove them. You might get away with using a radius sanding block without first using this beam, but it would take a lot of extra time stopping and verifying with your precision straight edge. An alternative would be the Aluminum Radius-sanding Beam, which costs twice as much. Neck Support Caul: Necessary. Some version of this is needed to safely hold the neck. Lined with balsa to protect the finish. Either buy this or make something similar. | ||

| |||

| FlySig |

| ||

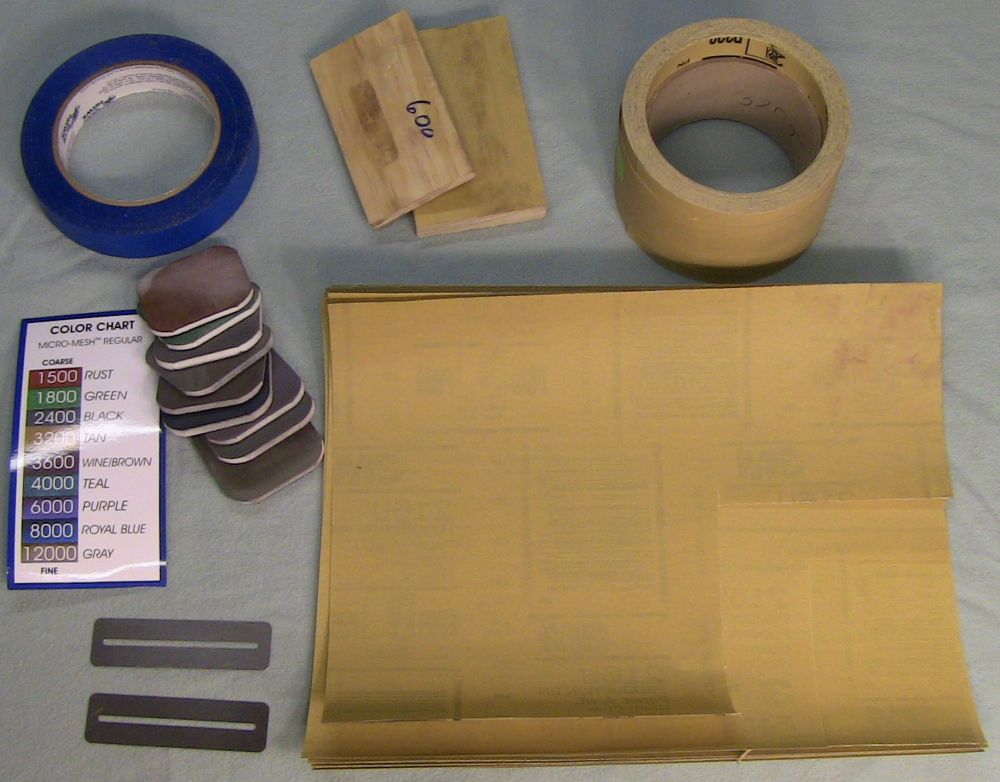

Joined: October 2005 Posts: 4081 Location: Utah |  Blue Painter’s Masking Tape: Necessary. A regular 1” roll works, though a narrower tape is needed for the upper frets. Get a 1/2” roll if you can find it. Otherwise you’ll be cutting the tape into narrower strips. Sanding blocks: Use scrap wood and a spray adhesive to attach sandpaper. Label the back side of the block with the grit #. 3M Stikit Roll Self Adhesive Sand Paper: Optional but handy. One roll will last a long, long time. Most useful for the fretboard leveler. 320 grit is perfect for leveling. You could trim sheets of sandpaper and use a spray adhesive instead. Call this one very nice to have but you can get by without it. Micro-Mesh Soft Touch Finishing Pads: Optional but very helpful. Use to polish anything. Final polish of the frets, remove scratches in the clearcoat, etc. 3M Gold Fre-Cut Sandpaper: Sheets of sandpaper. Necessary. 320 grit, 400, 600, and 800 will all come in handy for sanding the fretboard. One sheet lasts a long time. Much better than home improvement store sandpaper! No rogue large pieces of grit which leave scratches. One sheet of each will be enough for several refrets. Fingerboard Guards: Optional. These look like old fashioned razor blades. Place one over the fret and it protects the fretboard. Good for polishing the frets without having to use masking tape. I don’t use them very often. Edited by FlySig 2014-09-22 11:08 PM | ||

| |||

| FlySig |

| ||

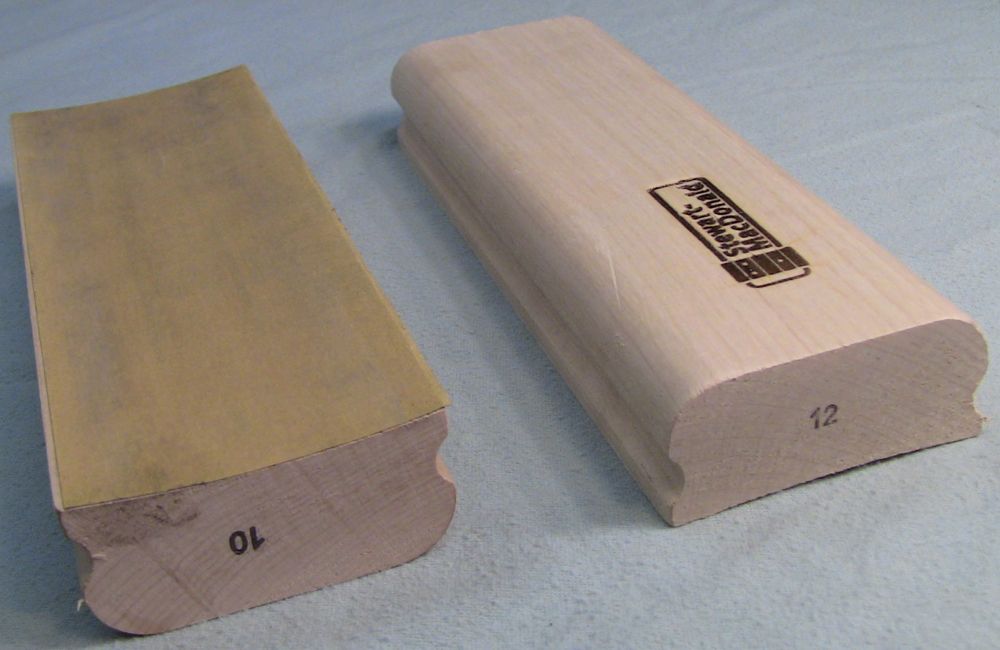

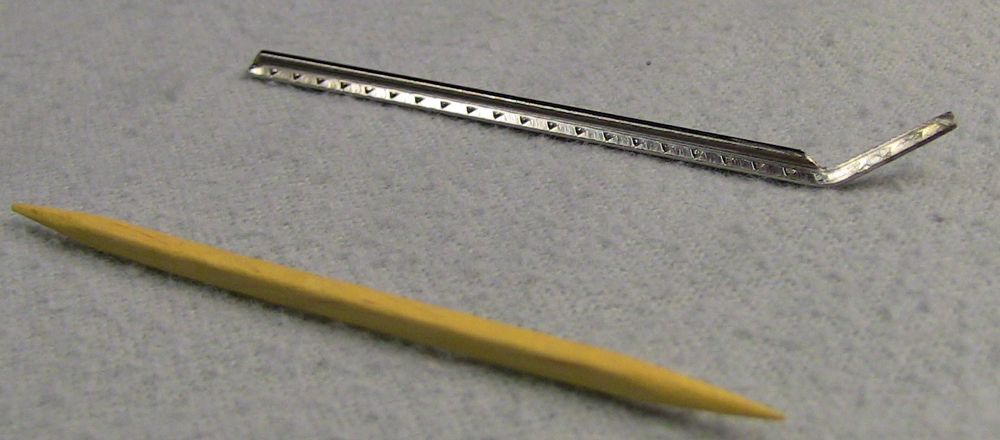

Joined: October 2005 Posts: 4081 Location: Utah |  Radius sanding blocks: For your Ovation you’ll want the 10” radius, which is the curve geometry. Buy the 8” long block. I call it necessary, but you could use the beam sander and check frequently with the radius gauge all along the length of the neck to ensure you are keeping the radius correct.  Fret wire tool: This is a homemade tool. Made from the actual fretwire you intend to use. It is about the same length as a tooth pick. Carefully file off the crown at one end and bend the tang into a little foot. Use this to measure the depth of the fret slots. If the slot is deep enough the foot will be below the surface as you slide it along the slot. This is a quick way to verify your slots have been sufficiently cleaned of old glue. You’ll have to file the barbs off of the tang to narrow it enough to slide in the slot.  Soldering Iron: Necessity. At least 20 watts, with a medium tip. The pencil tip is too small. File a notch in the tip so it doesn’t slip off the fret and burn the wood. Use the iron to heat a fret before pulling it. It softens the glue. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah |  Super Glue: You’ll need some thin cyanoacrylate glue and applicators. The StewMac glue and their “whip tips” work very well for repairing chipouts and small cracks. Alcohol: Fretwire must be degreased before use. Regular grocery store isopropyl alcohol works fine and is cheap and safe. Wood Glue: A good carpenter’s glue is a necessity. Acetone: (not shown) Optional. Will degrease fretwire and dissolve old glues. If you replace binding you’ll want acetone to remove glue residue. Will dissolve plastic bindings. Doesn’t seem to affect Ovation/Adamas neck clear coats, but check an inconspicuous spot. Can be used to remove old superglue.  Fret Bender: This is almost a necessity, especially if you’ll be doing multiple guitars. If you’re only doing one guitar you could try manually bending the fret wire with pliers. The key is to have the fret wire bent to an even arc, which can be tricky by hand. This tool isn’t cheap but it works so well and so quickly. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Nut Making Tools: If you replace your nut you'll need some additional tools. At this time I'll give some tool recommendations so you are aware of what you're getting into but won't discuss actually making a new nut. There are plenty of tutorials on the web which cover it quite well.  Chances are your old nut will be too low and you’ll have to install a new nut. If you’re going to make a new nut you’ll need some specific tools. A StewMac string layout ruler is very nice but not necessary. It lays out the spacing of the nut slots. Very very helpful. You’ll need a set of nut slot files. Get the more expensive rigid files, not the cheaper flimsy files. The flimsy ones bend easily and bind up in the nut slots. They don’t cut very quickly either. Nut shaping files are very nice to have but not a necessity if you already have some wood files. Finally, you’ll need some blank nuts. Measure the nut you’re replacing in order to get the correct replacement. I’ve found bone to be easier to work with than Tusq or the black GraphTec blanks. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Ok, so let’s get started! First evaluate your frets to determine if they can be filed level or if some or all need to be replaced. If your frets are worn below about .030” they are too low to be filed down any further. Use the FretGuru tool to measure the divots in the frets. A micrometer is a bit too fat to get down into the divots usually. Measure several frets, even the ones not showing wear, to see what you’re dealing with. If you replace only a few frets you’ll have to level them to match what is there. If you have to replace more than about 5 frets due to wear, you might want to just replace all of them. Pulling frets: To pull frets, first heat them with the soldering iron. Let the iron heat for 5 minutes or more. Then hold the tip on the fret for about 10 seconds at one end. Slowly move the tip along the fret, taking a couple of seconds or more to go from one end to the other. After about 30 seconds remove the iron and use the fret puller. As with almost all the tools and operations involved, use a loose grip and a gentle to moderate force. You’re not framing a house or wrenching on a car! So use a relaxed grip on the fret puller and gently rock it as you squeeze. When the tool is aligned with the fret you will feel it grab position. Then squeeze moderately to get the jaws under the fret. If it doesn’t go easily, it isn’t aligned properly. Squeeze the jaws under the fret, then slide the jaws a bit and squeeze again to lift a bit more of the fret. Don’t pull the fret out, just lift the fret the amount that the tool goes under. Now use one of those chip protectors by sliding it under the fret and placing the fret puller on top of the protector rather than on naked wood. Work along the fret until it comes loose. I find chipouts usually happen at the other end from where I started. In this photo a chipout is more likely at the bottom right end of the fret, so go a bit slower and more gently as you pull that last end free.  Edited by FlySig 2014-09-22 11:13 PM | ||

| |||

| FlySig |

| ||

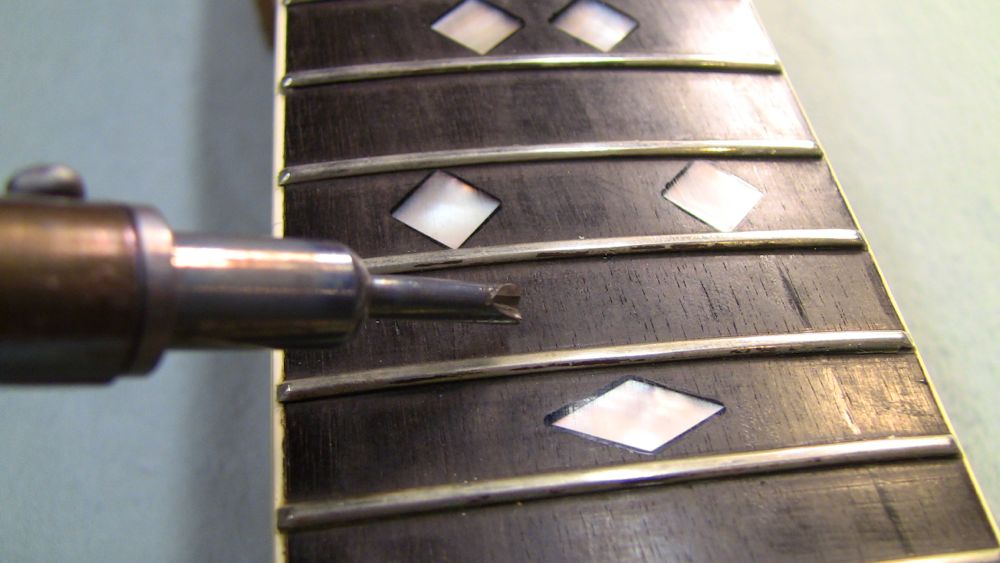

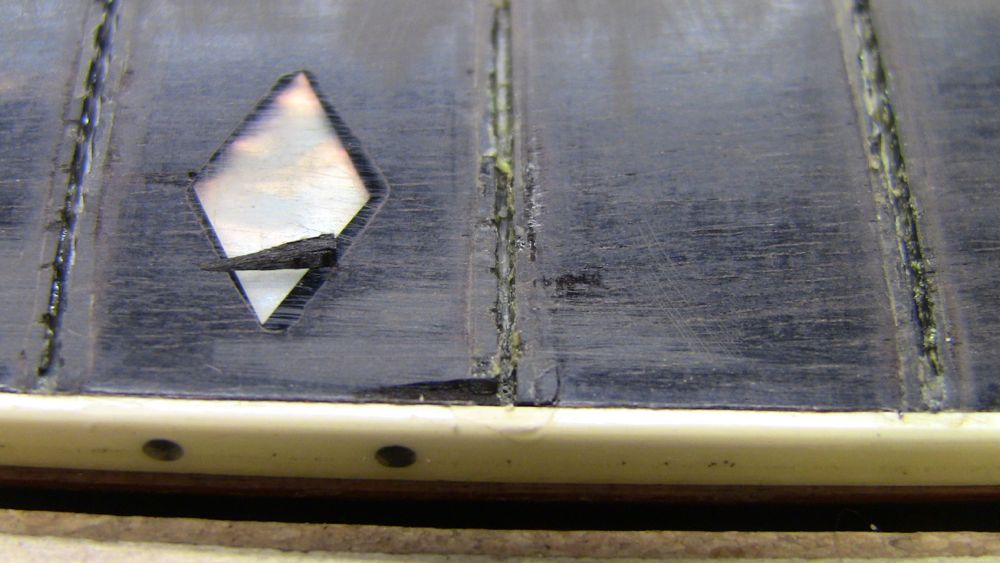

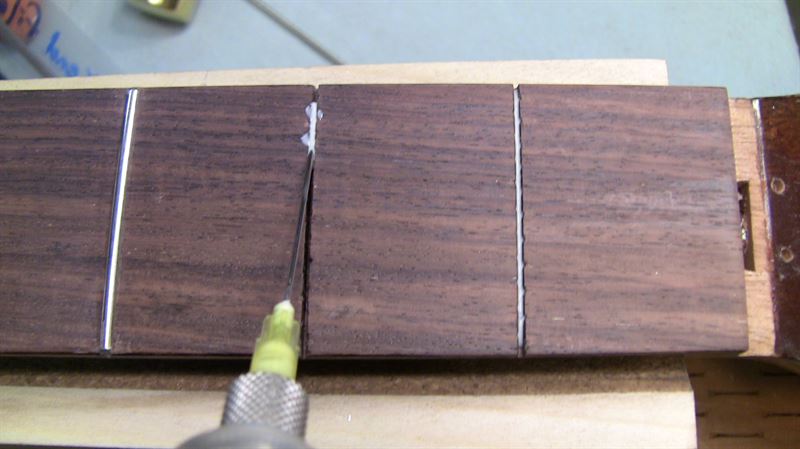

Joined: October 2005 Posts: 4081 Location: Utah | Fixing Chipouts: If you get a chipout, fix it immediately before pulling the next fret. Place the chip back where it came from and wick some thin CA glue. The StewMac whip-tips are perfect for this. Don’t worry if a bit of glue gets on the surface of the fret board or down in the slot, but try to keep the mess to a minimum. Use a toothpick to press the chip in tightly if you can. Here’s a picture of a triangular chip that came out. The chip is sitting on top of the pearl inlay, the hole it came out of is next to the binding. Notice, too, the mess created by using superglue (cyanoacrylate or CA) to glue in frets. Have mercy on the next person to do fret work and don’t use CA to glue in frets!  Cleaning fret slots: After you’ve pulled all the frets you’ll have to clean out the slots. Use your slot saw carefully to do this. You don’t want to widen the slot, so use straight motions and keep the saw aligned both vertically and along the slot. Use a relaxed grip on the saw! Move the saw slowly, taking about 1 second to go from one end to the other of the slot. You’re not sawing a 2x4 to build a house, you’re doing precision work here. Use care not to slip and damage the finish on the neck, especially if you’re using the 2 bladed StewMac saw. A minor scratch on the fingerboard won’t matter because you’ll sand it out later, but still try to be careful. If the neck is bound, use a lot of care not to bang into the binding with the saw because the binding will come loose quite easily. A block of wood held against the binding can help prevent it from being knocked loose. Use the fret cleaning tool to get the bits out of the slot, and use your home made fretwire tool to ensure the slots are deep enough. | ||

| |||

| FlySig |

| ||

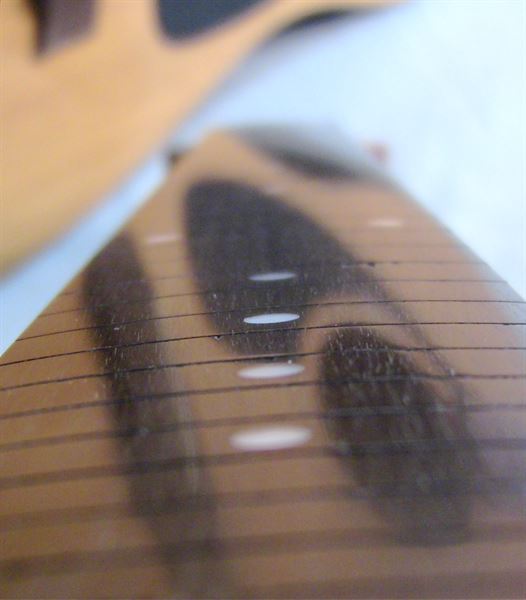

Joined: October 2005 Posts: 4081 Location: Utah | Sanding the fingerboard: Once you’ve gotten the slots cleaned out deep enough, it is time to sand the fretboard. Loosen the truss rod all the way (you can do this as soon as you take the strings off the guitar). Use the straight edge to verify the neck is straight. Some necks need a tiny bit of tension on the truss rod. Use care in this step. There may well be a hump above the guitar body on an acoustic. So adjust the truss rod so that the neck is straight through the middle part. I’ve found several necks with a hump in the 14th to 20th fret area, and also in the 1st fret area. You can loosen the truss rod all the way and then sand the entire length level, but it is more work than is necessary. I remove the nut and tuners, and protect the top of the guitar from accidental scrapes. The first few passes of the beam will show where the high spots are, as seen in this photo where the 1st/2nd fret area is high, and the 18th/19th fret area is high.  Use the beam to sand out the humps. Use a relaxed grip on the middle of the beam, and let the weight of the beam do the work. Move slowly, taking up to 2 seconds to go all the way from one end to the other. Again, you’re not doing rushed work on framing a house, so take your time and don’t use too much force. Check your work frequently. Use the radius gauge to verify you are not changing the shape of the curve significantly. Start with 320 grit paper. Use the straight edge frequently to verify the entire board is level. Then go to the radius block with 320 grit to get the curve even all along the length of the neck. Use the radius gauge frequently. Then double check with the straight edge that you’re not creating low spots. This step is one of the most important, so take your time and be precise. Once the shape is correct, switch to higher grit papers. 400, 600, 800 of the tan fre-cut paper. You can use a plain flat wooden block or you can glue the paper to a radius block. When you remove old paper, fully remove all the glue. Any glue bits will become high spots on the new sandpaper and will gouge the surface of the wood. After 800 grit you can go even higher using wet/dry paper up to 2000 grit. The little polishing pads also work well, but sandpaper is cheaper.  Once the board is sanded to a fine finish, recheck the depth of all the fret slots to be sure they are still deep enough. Then use a triangular file to knock the edges off the top of the fret slots. Fretwire has a slight roundness to the underside joint between the tang and the crown, so your slot needs a slight bevel at the top so that the fretwire will seat all the way flush with the top of the fret board. Edited by FlySig 2014-09-22 11:25 PM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Cutting and prepping new frets: Use the alcohol or acetone to wipe the oils off the fretwire. This is a mandatory step! Fretwire needs to be slightly more curved than the top of the fretboard so it seats properly. Use the fretbender tool to curve the entire length of fretwire. Curving small segments, such as pre-cut frets, is more difficult but is possible. Starting with the upper frets because they are longer, cut a fret just slightly longer than what is needed. Perhaps 1/8th inch too long. Longer is wasteful and unnecessary. Just don’t be too short! If it is too short you can use that fret for a lower fret because they are shorter. If the neck is bound it is a much more fiddling job. You’ll have to nip off the ends of the tangs. I don’t recommend refretting a bound neck for one of your first few. Installing new frets: Use diluted carpenters glue, approximately 2 parts glue to 1 part water, and run a small bead into the first slot. Using many light taps with the hammer, seat the fret. A little bit of glue will spit out the ends of the slot, so wear older clothes and don’t work at the fancy dining room table. Don’t hit at all hard with the hammer or you’ll deform the fret making it unusable.  For an acoustic guitar you’ll want to support the soundboard when hammering in the upper frets. A small hand-held sandbag works well. Removing the neck from an electric guitar makes it a lot easier. Once the frets are in, use the straight edge to find any which need to be hammered in more. If the fret board was sanded correctly, and if all the frets were seated properly, the frets should all be level with each other. Trim off the ends of the frets as close to the neck as possible with the fret cutter, using care not to scrape the finish. Use the fret end file to carefully file the end of the fret tang all the way flush with the edge of the neck. Don’t use masking tape yet! Just use a lot of care, filing perpendicular to the edge of the fretboard rather than along the edge of the fretboard. Get that tang filed so that you cannot feel it with your fingers. Those little scuffs in the clearcoat polish out surprisingly well.  Edited by FlySig 2014-09-22 11:24 PM | ||

| |||

| FlySig |

| ||

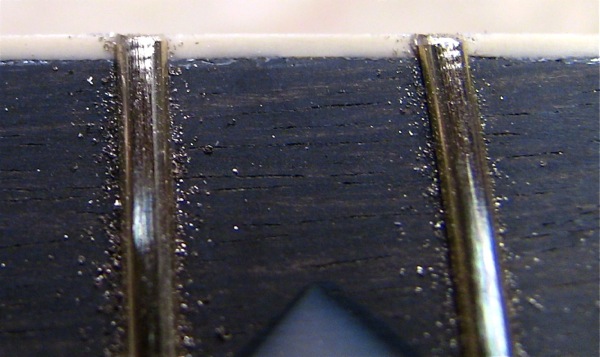

Joined: October 2005 Posts: 4081 Location: Utah | Leveling and polishing new frets: Be sure to protect the top of the guitar and the headstock, especially during this part of the process. The next step is to level the frets using the sanding beam and the 320 grit paper. Lightly run the beam once across the frets, covering the entire span of each fret. Now look for where frets have been flatted slightly by the sanding. Those frets are a bit high. Now slowly and carefully beam sand until all the high spots are down level with the other frets, but don’t sand down into the lower frets. Use the bevel file to bevel the ends of the frets. File all the way to the edge of the fretboard, but not into the wood. If there is binding, use care not to remove any of the plastic which is soft and files away easily. Run your fingers along the length of the edge of the fretboard to find fret ends which poke out. If you hadn’t filed the ends of the fret tangs flush earlier, now is when you’ll really feel it. Now you can tape the entire fretboard with blue tape. Don't tape prior to this point or you'll gum up your files and fail to get the fret ends filed flush. Get the tape up against the frets but not riding up the side of the frets. Crown the frets with the crowning file. Mark the top of each fret with a blue Sharpie, then file slowly and carefully until just a sliver of the blue remains along the top of the fret. You only have to crown frets which were sanded. The un-sanded frets already have a smooth crown on them. Use the end file to smooth the bevels. If you don’t tape the fretboard you’ll put tracks on the wood like these. Files without a smooth edge will also leave these tracks.  Polish the frets however you prefer. You can use polishing compound and a felt wheel on a Dremel tool, or you can use StewMac polishing pads. The pads work fine and don’t take too long. They’re a lot cleaner than using the Dremel, too. If there are gaps in the ends of the fret slots you can fill them with dilute carpenters glue or other clear coats. Peel off the blue tape, wipe everything clean, and the frets are done! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2346 Location: Pueblo West, CO | Nicely done! This is a great tutorial. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Thanks, Dan. Your threads have given me the confidence to do more extensive work on my guitars. But I'm not quite ready to replace entire tops yet. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2346 Location: Pueblo West, CO | Thanks and you're welcome. IMO, that's what the BFLG is all about. No one should be afraid to work on their own guitars. They aren't magical. They're just bits of wood, plastic and metal. Edited by DanSavage 2014-09-23 4:37 PM | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | DanSavage - 2014-09-23 12:17 AM Nicely done! This is a great tutorial. Ditto! Thanks FlySig. Like you, I've been inspired by the BFLG, particularly DanSavage's 1619 Rebuild, and this is so timely for me. I finished fixing my friend's Ibanez with a broken neck, and when I removed the fingerboard with heat, some of the fret ends popped out of their groove. I was just thinking, "After CA-ing the fret ends into place, I'm going to need to learn about dressing the frets." So thanks a bunch for your timely post! Now, I'm inspired to get the appropriate tools and start dressing my own frets! Edited by arumako 2014-09-23 5:57 PM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Here is a quick addition about crowning frets using a concave fret file. These files work very well but can put chatter marks on the ends of the crown at the edge of the fretboard if the file angle gets too steep. It can be felt as a rough stepping of the file as it goes over the end of the fret. Here's a picture of the chatter marks and a picture to illustrate in an exaggerated way an incorrect angle of the file which causes the marks.   | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | At this point I've used 3 different fret wires on 3 different guitars. Two were nickel silver, one was EVO Gold. The nickel silver were easy to work with, as the metal is is relatively soft. Nickel silver takes a bend quite easily which means it is easy to radius, but it also can be bent or kinked when hammering the fret into the slot. Nickel silver files quite easily. Stew Mac medium fretwire #152 is a very close match to the current Ovation factory dimensions. This would be a fine choice for any acoustic or electric guitar. Allparts fretwire is of unknown brand. It seemed very slightly stiffer than the StewMac wire in terms of holding a radius when hammering a fret into the slot. Otherwise it was the same to work with as the Stew Mac. EVO Gold wire is a whole different animal to work with. I'll post a thread about it shortly. Overall I really like working with it. EVO is much harder and stiffer than nickel silver wire, which has both positive and negative aspects. I will probably only use EVO from now on when doing a complete refret. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | Very Cool! Thanks for sharing your journey. Look forward to hearing more about EVO...so much stuff to learn! | ||

| |||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |